VELES-AGRO

tillage equipment and spare parts

Reaper for harvesting sunflower CX 6

0 uah.

The header for harvesting sunflower CX in a unit with a self-propelled combine harvester is designed for harvesting sunflower in the stage of full ripeness.

Provides high-performance and high-quality work of the combine with the least losses.

In one pass through the field, the combine harvester with the header provides: cutting the tops of the plants, grinding the seeds from the baskets, separating the heap, collecting the peeled seeds in the hopper, chopping the threshed baskets and spreading them across the field.

It is used in all soil and climatic zones of sunflower cultivation in fields with a slope of up to 8 °. The harvester is most effectively used when harvesting sunflower in the full ripeness stage at the optimum harvesting time at speeds of up to 6 km / h on crops with the following main characteristics:

— stem height not more than 230 cm;

— the distance from the ground to the most drooping baskets is at least 60 cm;

— seed moisture from 12 to 20%, basket humidity not more than 60%;

— the weediness of the field must meet accepted technological standards and should not exceed 5%, while the weeds should not impede the normal passage of the technological process;

— the header is designed for operation in fields with a slope of up to 8º at an air temperature of minus 5 to plus 45ºС;

— the fields on which the header works must have a level surface. In the fields there should be no foreign objects (stones, metal objects, etc.).

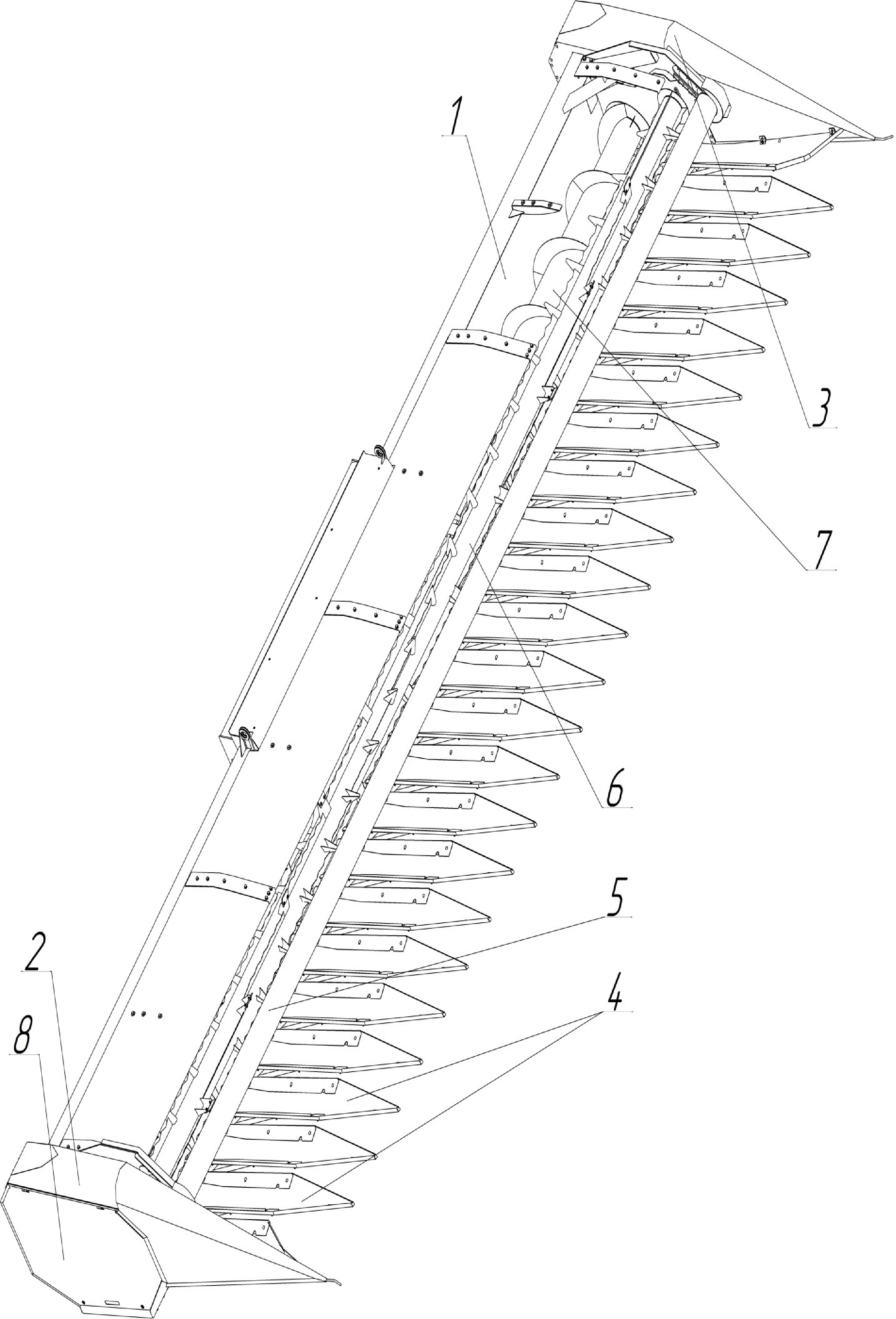

Header platform: 1) header frame; 2) the right sidewall; 3) the left sidewall; 4) stem lifters; 5) fairing; 6) reel; 7) auger; 8) protective shield.

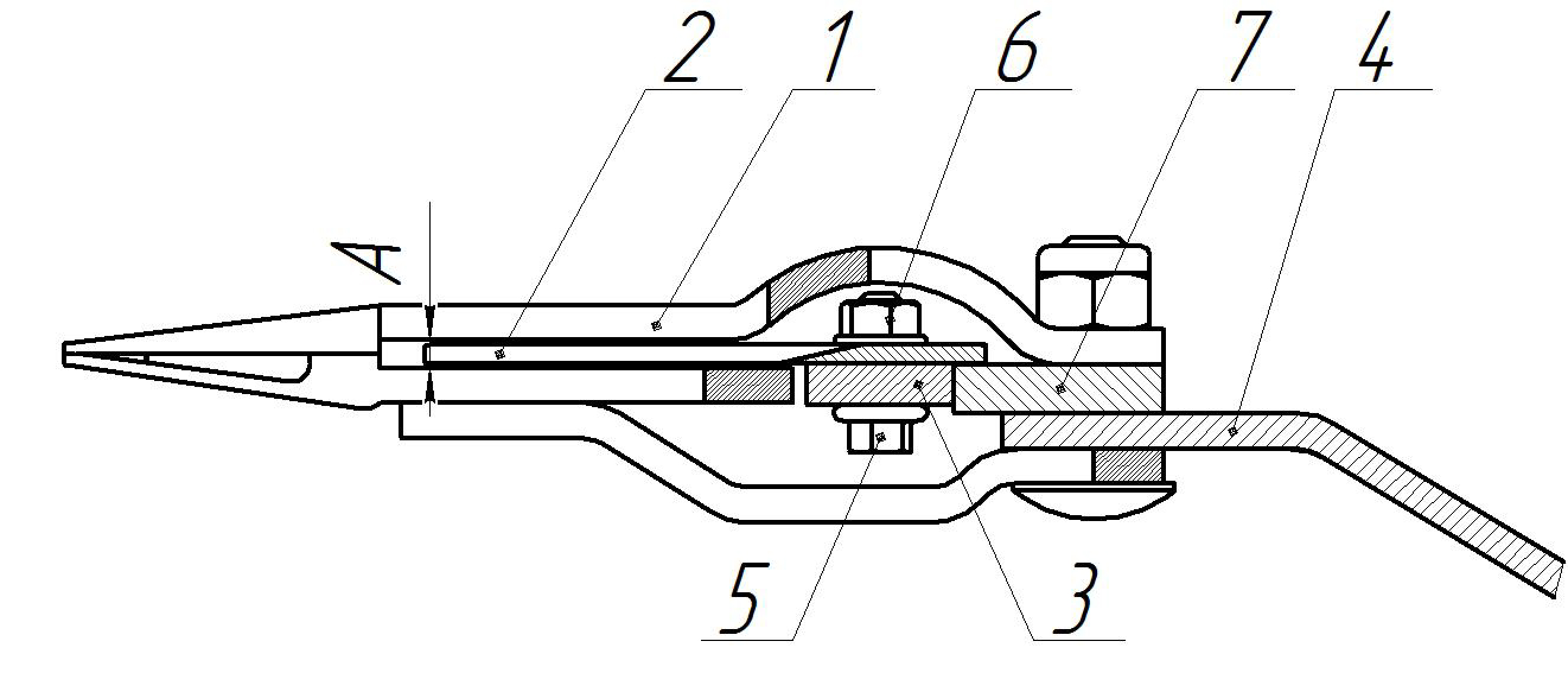

Cutting apparatus: 1) double finger; 2) segment; 3) the back of the knife; 4) cutting beam; 5) a bolt; 6) nut; 7) guide bar; A) double finger clearance.

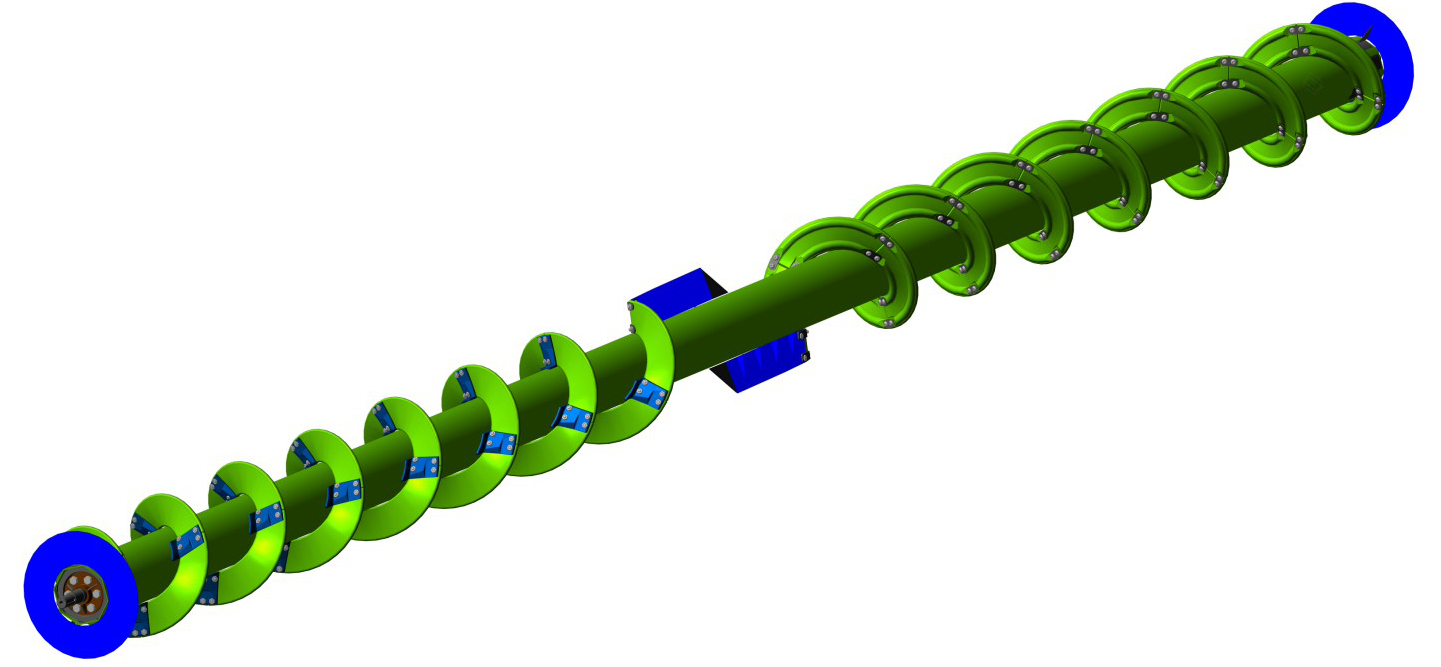

Polyamide screw. As an option, the header can be equipped with a polyamide auger instead of the conventional metal auger. As tests have shown, the use of a polyamide screw has a number of advantages:

— reduced vibration due to the softness of the material of the auger turns when solid objects enter the header;

— thanks to the segmented design of the auger, it is possible to quickly and easily replace a damaged auger coil without welding;

— due to the softness of the material of the auger coils, damage to the bottom of the header becomes unlikely;

— no corrosion of working surfaces.

Harvesters and carts

Reaper for harvesting sunflower CX 8.4

Reaper for harvesting sunflower CX 8.4

and don't include VAT 20% and discounts

VTG UNIVERSAL SINGLE-AXLE TROLLEY FOR HEADER TRANSPORTATION

VTG UNIVERSAL SINGLE-AXLE TROLLEY FOR HEADER TRANSPORTATION

and don't include VAT 20% and discounts

Universal trolley СХТ for transportation of the header

Universal trolley СХТ for transportation of the header

and don't include VAT 20% and discounts